HOME > Product lineup > About Ceramics

About Ceramics

About Ceramics

Ceramics is non-metallic and inorganic material which is high-temperature-treated in the manufacturing process such as pottery and porcelain, cement, bricks, glass and etc. Ceramics has the property of heat/abrasion/ corrosion resistance not shared by metallic and organic materials.

About Fine Ceramics

In addition to the characteristics of Ceramics, Fine Ceramics prepared by high-purity material has more advanced functionality. Fine Ceramic products are manufactured under precisely-controlled conditions.

About materials

MARU-U has plenty of experience and knowledge with materials to make the products our customers want.

Alumina(98% / 99.9%)

Features:Alumina, a melting temperature of about 2,050℃, has hardness second only to diamonds, and pure Alumina is an insulator. Alumina is widely used as a leading ceramic material due to its superiority in corrosion/abrasion resistance and high purity which is considered as generic property of ceramics, and is also inexpensive.

Used mainly for textile machinery parts, etc.

Forming method: Injection/Press/Extrusion molding

Zirconia

Features:Zirconia, a melting temperature of over 2500℃, has high strength and high toughness at normal temperature. Zirconia also has superiority in corrosion/abrasion resistance, bending strength, and good surface smoothness, and is currently widely used such as sliding parts, etc.

Used mainly for various sliding parts, etc.

Forming method: Injection/Press/Extrusion molding

Silicon nitride

Features:Silicon nitride has high thermal shock resistance in addition to standard characteristics of ceramics, and its intensity is not decreased at high temperature.

Used mainly for engine and gas turbine components

Forming method: Injection/Press molding

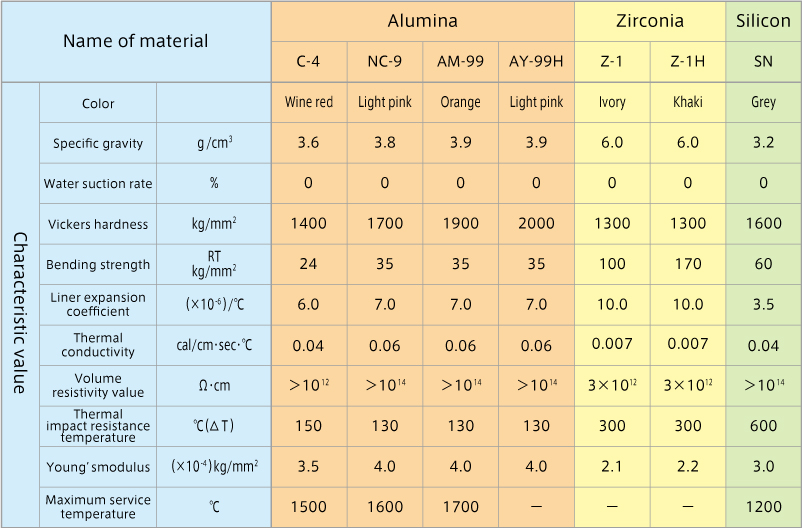

Materials and characteristic value